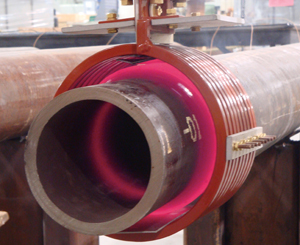

Pipe End Heating

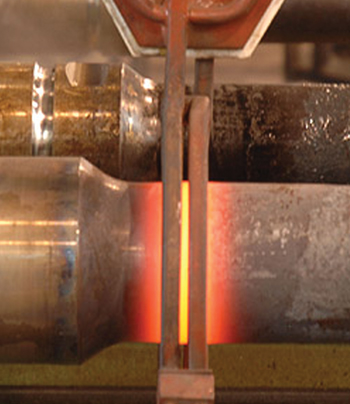

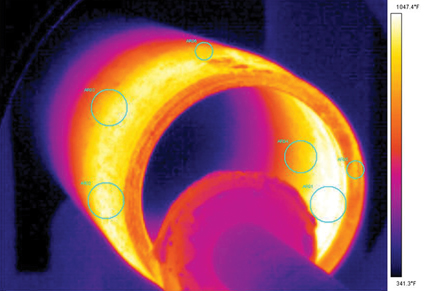

| The precessing of pipe ends includes drilling, threading, welding and other types of mechanical deformation which may require heat treatment to harden the metal or to eliminate residual stresses. In addition, tube ends are often heated and then upset (formed) to increase or decrease the diameter or wall thickness to allow pipes to be joined end-to-end.

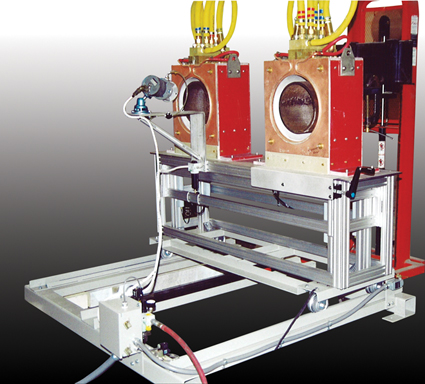

Pillar Induction pipe-end heating systems are designed for a variety of these applications including: • Preheat for welding & swaging Features Include: Click here to view the Pipe End Heating Data Sheet. |

®

® ®

®