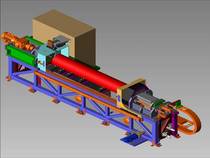

Horizontal Scanner

|

These installations have processed bars, tubes, and pipes, and they all have three sections: infeed, heating/quenching, and outfeed. The drive mechanism, controls, and complexity varied, depending on the application, industry, and country of destination, but Pillar quality is what our customers have always counted on. The diameter, length, wall thickness, final temperature, and throughput have been varied, but consistency, repeatability, and a quality end product is what our customers tell us remained the same.

Capable of heating cylindrical parts from 17 inches to 200 inches, up to a 19 inch diameter, these large Horizontal Scanners are used for progressive heating and are fully integrated with induction power, quench systems, rotational drives, servo motions and system controls. While the part is rotating, the induction coil (with integral quench) will travel horizontally along the length of the shaft while induction heating, simultaneously quenching the parts. The heat station is located behind the scanning envelope. |

|

®

® ®

®