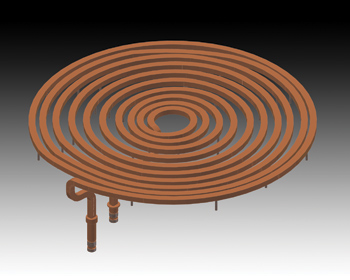

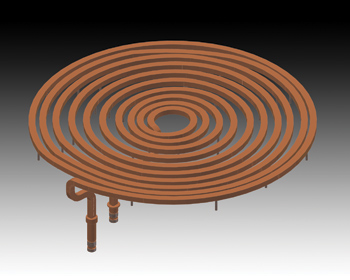

Induction Heating for Epitaxy

| Epitaxy refers to the method of using chemical vapor deposition (CVD or MOCVD) to deposit a monocrystalline film on a monocrystalline substrate. The deposited film is denoted as epitaxial film or epitaxial layer. This process is used for the production of semiconductors and LEDs. Pillar MK11 series generators provide consistent and reliable induction heating for the process.

System Features Include:

- No consumable components (i.e. tubes)

- 47% less power directly used by RF generator

- IGBT power control instead of tube so no more tube changes or power drifting

- 96.7% conversion efficiency

- Facility has to dissipate only 24,000 btu instead of the older requirement of 215,000 btu

- Less demand on facilities which could require expensive facility improvement as more equipment is added

- Less floor space than RF unit, 17 square feet versus 27.5

- Mark 11 requires access to one side only. Allows for back to back or against the wall mounting

- Better temperature uniformity

- Plenty of power to reach the hottest process temperatures. Less faulting for those higher demand processes

- Does not require any facility changes to install

- Direct modern replacement for motor generator and SCR technology

- Push to test tuning verification

- Insertable control board IC devices to expedite servicing

- Single main control board within a separate lockable door for safe access

- NEC and NFPA79 wiring codes

- Isolation output transformer

- Parallel tuned output circuit

- Constant voltage control circuit transformer

- Possible energy rebate from federal and/or state governments

Click here to view the Pillar MK11 Epitaxy Power Supply brochure.

« Back |

|

®

® ®

®