|

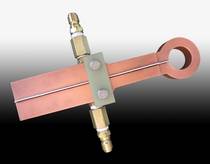

The success of any induction heating application is related directly to the selection and design of the work coil (or inductor). This design is influenced by a number of factors, including the dimensions and configuration of the part to be heated, the heat treat pattern required, whether the part is single-shot heated or scanned, and the amount of power available. Most scanning application employ inductors with one or two turns. Single turn inductors are generally machined copper structures with precise dimensions.

Pillar utilizes many innovative coil designs and manufacturing techniques to achieve proper heating of your product, based upon our staff’s broad experience. Trust your application to our experts who will provide the most efficient and productive solutions. Coils are designed by our team of engineers and are manufactured in-house, to provide high quality products at a competitive price.

« Back |

|